Luzern 1994 - Protection Function of Sports Surfaces

L01 Design of Sports Surfaces based on Biomechanical and Mechanical Concepts

Design of Sports Surfaces Based on Biomechanical and Technical Concepts

Hans J. Kolitzus

In this presentation, we will discuss how the considerations of various disciplines could be used for improvement of sports surfaces. The test procedures as such - regardless whether biomechanically or technically oriented - are not at issue here as we focus on the surfaces and how they can be designed by means of theoretical and scientific methods to comply even better with the needs of sports. You will hear various statements which might produce objections. However, we are not here to focus on trivial statements but to present non-trivial/unusual ideas and to discuss their validity.

Up front we must acknowledge that all of the investigations performed since 1960 has had little effect in practice - statistically seen. The publications of Prokop, Baumann, Nigg, Segesser, Otto-Graf-Institut, Kolitzus, Landesgewerbeanstalt Nürnberg, McMahon and Greene have been perceived by only a very few companies and used for the development of better surfaces. It is now the time to review the available results and to evaluate them rather than starting with new ideas over and over believing that the stone of wisdom would be found.

Difficulties in Practice

Concerning the translation of general knowledge results into reality, we must also understand the obstacles in practice.

There is, for instance, the fact of rather little interest at the consumer (representatives of building owners and sports associations - the athletes often have only little influence) level in function-ality of sports surfaces.

The market is also widely dominated by preoccupations and routines. It is a common experience that the expectations for a sports surface are formed by earlier experiences athletes, coaches, and teachers have had with certain sports surfaces through using them for many years. They have adjusted themselves to the peculiarities and possible shortcommings in a way that they do not realize them and cannot, may be will not, imagine better performance of sports surfaces. As a consultant you cannot make a worse proposal than to try to persuade such users to select a better surface.

Another common obstacle is the low information level of the responsible persons in the administration of sports facilities. In such a situation it is easy for clever representatives to tell incredible stories and to eliminate serious competitors.

Company Associations

About 15 years ago, an association was founded by companies in Germany to ensure the quality of sports surfaces. This was commendable and I supported this as much as I could. However, the original idea has been restricted by economical aspects in a way that the intent, to improve the quality of sports surfaces by an agreement to overcome the common obstacles has failed. While regrettable in this one respect, it is welcome in another respect: it ended the associations try to undermine the independance of the test laboratories. Looking to the future, the good news is that from now on alternative initiatives have a chance for an effective improvement of quality which was suppressed by the overall RAL quality monitoring system.

Facing such a situation, it was actually a bit risky that I presentated papers in the United States on the positive effect of the DIN standards on the development and the quality of sports surfaces. However, fortunately, there are also other people in the public administration and the industry who, regardless of all the obstacles and difficulties, insist that sports surfaces must be functionally designed and who provide proposals regardless of their economical success. In order to determine if they achieved progress, those people need reliable and valid technical investigation methods. In this respect, the DIN standards have earned considerable merit.

Classic Fields of Sports Surface Technology

Two areas may be considered classical in sports surface technology: sports hall surfaces and synthetic athletic surfaces for track and field events. In both areas, impressive examples can be found which are suitable for this Seminar. Prior to the details of these matters, some other information.

Disciplines

It seems to be reasonable to address the relationship between the different disciplines. May be, it helps to bring the more or less unspoken reservations and preoccupations of the biomechanical and the technical oriented scientists and engineers to objective grounds. I suggest that there are the following primary disciplines:

- Material Technology

- Physics

- Measuring Technology

- Sports Technology

- Medicine

The Sports Surface Technology is based on the first four areas and influences the Material Technology, while Biomechanics refer to the latter four areas and influences the Sports Technology. The question of which discipline is of greater importance is obsolet considering that both disciplines deal with different tasks within our scope.

Sports Surface Technology =

function oriented material testing for improvement and control of the technical products;

Biomechanics =

investigation oriented mainly to mechanical aspects of the human body in respect to improvements of the Sports Technology.

Material Technology

We will not talk too much about Material Technology. It is true that the possibilities of new materials - such as physically linked synthetic foam, dimensionally stable synthetic panels, new adhesive technologies coating systems with special strength characteristics and high performance wooden panels - are the critical starting points for the development of surfaces in the right direction.

However, there are several technical details which have proved to affect the function of the surfaces considerably. Despite of the enthusiasm for highly developed functional sports surfaces, they must first of all withstand the loads produced by the sports use.

This includes questions of permanent deformation, evenness, forming of little bubbles in PUR-coatings or visibility of joints (i.e. joints of panels of load distribution slab) and impact effects. A very important aspect is also in how far the processing or installation technique is dependant on workmanship and ennvironmental conditions (climate). For instance, a coating system is suitable only when it can be properly processed within a relatively wide temperature range (+5C until 40C) and will then still cure securely and within such a short time that upcomming rain will not destroy the work of a full day.

Another problem may be created by improper compatibility of materials. If, for instance, a reinforcement fabric is embedded in a coating system, this is useful only when sufficient transmission of transvers (Schub) tensions is available. In addition, the hardness and the strength of the coating system (which is called the Matrix) must be adjusted to the elongation capability and strength of the fabric in order to achieve a combined effect with sufficient loading capacity.

Physics

Let us consider aspects related to physics.

Although this issue has been discussed earlier, some information has to be amended under the aspect of the principal functioning of sports surfaces. Physics provide the laws which surfaces inevitably have to follow. These laws must be recognized and used appropriately. Since these matters are connected with mathematics they are rarely comprehended by the more or less practically oriented industry. I am trying to briefly explain the essence in short without using too many formulas.

These are some of the elements of the elasto mechanics.

Bending Resistant (Stiff) Slab

The basic model of a surface consists of a stiff slab which is elastically supported (see fig. 1). The slab has a certain inert mass of kg/m2. On the surface, athletes move around using certain movement patterns. They themselves represent spring-mass-systems. We distinguish the static and the dynamic behavior.

The deformation characteristics of an elastically supported stiff slab are described by a set of connected differential equations of 4th order. Their solution can be calculated by using a Navier's series. In order to simplify the situation, I have reduced the case to a two dimensional problem which is an elastically supported beam. The analysis of the mathematical solution revealed very interesting information which was proved during development of real surface systems.

The differential equation of 4th order for the two dimensional case reads as shown by formula 1 (see also fig. 2).

We can see that the relation between the stiffness of the slab and the bedding number of the elastic layer are critical for the overall mechanical behavior. Stiffness means the product of the modulus of elasticity [N/mm2] and the moment of inertia [mm4]. While the first parameter is material related the second parameter is dependant on the thickness d [mm] only and is a pure geometric entity (see formula 2).

It is obvious from experience that the thicker the slab the stiffer it becomes (i.e. it bends less with the same load). As a matter of fact, the bending deformation of a double layered slab is only 1/8th of a single layered slab with the same load.

Bedding Number

The bedding number K is equivalen to the spring number [N/mm] of the one-dimensional structured spring. With surfaces we do not have single springs but a continuous elastic bed the total elastic effect of which is dependant of the size of the area considered. The bedding number can be regarded a constant as a first approximation. Under this proposition, a slowly applied load reveals a linear force-deformation profile.

However, in practice, the bedding number increases with the deformation. This phenomenon is called a progressive elastic characteristic. This effect can be seen in a real test situation as the force reduction decreases with increase of the impact exerted by the test apparatus. Since this is an interesting performance characteristic, force reduction should be determined with different drop heights of the artificial athlete's missile (this causes variation of the impact) as it is actually proposed in DIN 18032. It reveals that point-elastic surfaces show a reasonable dependance while area-elastic surfaces react much less or not at all in some cases (see fig. 3 - in preparation).

Resilience

Resilience is the measure of the deformation in relation to the load of the surface. In terms of elasto-mechanics it depends on the ratio between stiffness and bedding number: the lower the stiffness and the lower the bedding number the softer the surface. With the example ot the continuously elasticly supported beam, a deformation curve w(x) in [mm] results as a solution of the above given differential equation as can be seen in formula 3. This formula represents a damped sinusoidal wave in mathematical/physical terms. The deformation at any distance from the loading point is a linear function of the load when the elasto-mechanical entities EJ and K are given.

For the maximum deformation at the loading point with a single point load, the formula shrinks because of x=0 to formula 4.

The formula also reveals that the resilience is a function of the stiffness and bedding number. The surface is softer the larger the value of w(x=0) with a constant load of F. If the stiffness (EJ) is increased four times, the resilience changes no more than 40 % ( double EJ -> 20 %). However resilience changes by 70 % with a doubled bedding number (four-fold bedding number -> 180 %).

Deformation Trough

For the performance of sports surfaces the characterisric 'extension of deformation trough' is vital. It is governed by the ratio of stiffness ./. bedding number. The lower the stiffness of the load distribution slab and the higher the bedding number, the smaller is the extent of the deformation trough. Thus, we can design the deformation trough from extreme small (point-elastic) to extremely large (area-elastic) with constant resilience (see fig. 4).

According to DIN 18032, the extent of area-elasticity is measured using the parameters Wxxx (W500, W250, W100 and W45: see fig. ...). Consideration of the above mentioned equations reveals that this approach is reasonable. According to the theory, the parameters

Wxxx = w(x=xxx)/w(x=0)

are constants for a specific surface system regardless of the load. A problem occurs if - instead of Wxxx - the slope of the trough at the loading point is regarded as critical. Evaluating the formulas we find that the slope increases with the deformation w(x=0) and Wxxx= const regardless of the surface system. The slope is therefore not a constant characteristic of surface systems.

We can see from the theoretical analysis that area-elasticity and point-elasticity - expressed in terms of Wxxx - are the origin and the end of a continuous scale. There is a continuous transition from point-elastic to area-elastic. Surfaces in between these characteristics are called 'mixed-elastic' or 'small-area-elastic'. DIN 18032 provides the parameters but does not define the limits to distinguish the various types of surfaces. Since such definitions are needed in practice, the appropriate specifications of the Swiss School of Physical Education (Magglingen) Norm ETS 203 or the Austrian Regulation published by the Austrian Institute for School and Sports Facilities are referred to.

A special type of deformation characteristic is shown by the so-called combined systems which are produced by superposition of the point-elastic and the area-elastic principle.

Stresses

The stresses inside the materials are due to the ratio stiffness ./. bedding number since the bending moment of the load distribution slab is controlled by this ratio. The stresses, which reach a maximum at the top and the bottom of the slab cross section, and the limiting stresses for failure are critical for the bearing capacity of the slab.

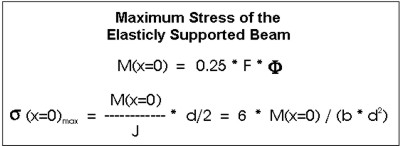

From the above equations, the bending moment M(x=0) and the stresses at the top and the bottom of the slab sigma(x=0)max revealed through formula 5.

From simple considerations with the elasticly supported beam, we can gain the knowledge of what the limiting parameters in the design of sports surfaces are and which parameters should be utilized in order to adjust the performance of the system in the proper direction.

Consideration reveals that the stresses at the top and bottom of the slab decreases to half if the thickness of the slab is increased by the factor of two. On the other hand, the bending moment M(x=0) is a consequence of the ratio EJ/K. Thus, it is most effective for the design to produce the load distribution slab with a material which allows for extreme high stresses. The thickness can then be reduced to a minimum. We know from material technology that the Modulus of Elasticity of the materials available for construction purposes exhibit values as shown below:

Hard-PVC = 5000 N/mm2

Polyethylen= 1000 N/mm2

Particle Boards= 3000 N/mm2

Plywood= 7500 N/mm2

The stresses at break vary between 10 bis 20 (40) N/mm2.

Dynamic Performance

We have now reached the dynamic performance. Here we consider not only the inert masses but also their damping effects. Since the dynamic systems have been dealt with earlier (Dr. Binder), only a few additional remarks are left to be mentioned.

In terms of Physics, sports surfaces together with the athletes running on them are multi-mass swingers. Such systems can hardly be described in simple equations. However, some terms should be noted since they are the keys for understanding the swinging problems.

On one hand, the resilience reduces the impact force of a landing athlete and has thereby a protective function. When the spring number is small (this means the surface is soft) a better protection effect is provided. On the other hand, the resilience can adversely affect the athlete's performance under certain circumstances.

The presentation of Dr. Binder has shown what a damped resilience means. By an increase of the damping number, a periodically abating or subsiding swing is produced. Raising the damping number with constant spring number, there is a point when the abating effect is already terminated after one swing period.

This effect can theoretically be utilized to eliminate adverse impact vibrations when runners hit hard surfaces with their heals. According to Prokop, this is the reason for the so-called Tartan syndrome. Different from filtered electrical signals, the vibrations will not occur or exist any more. In order to achieve this with the very high spring numbers of real synthetic surfaces, the damping parameter must be extremely high - higher than available in practice.

This is caused by the fact that a certain minimum deformation is needed to make the damping effect work. However, even if the shoe is controlled by the surface in a way that a effectively damped movement is achieved, the foot can oscillate inside the shoe.

On sports hall surfaces and gymnastics mats, damping can reduce the rebound effect on the feet and thereby improve the stability of the athlete's landing.

Mass is a typical characteristic of area-elastic sports hall surfaces. In order to better understand the effect on the swinging process, the term 'effective swinging mass' is used. For this, the swinging sports surfaces is thought of as a one-dimensional swinging system. The relevant mass is obviously dependant on the size of the deformation trough. Calculations show that only about 0.5 m2 of the area surrounding the loading point is effective. This amount is about 0.05 to 0.1 m2 with mixed-elastic (small-area-elastic) surfaces.

The larger the effective mass, the harder the first contact (impact) of falling body with the surface since the mass of the surface has to be accelerated from nought whereas the impacting body has a certain speed already. Opposite to this, point-elastic surfaces do not have a considerable effective mass. They have therefore a favorable effect in respect to protection function. As a result, the effective mass can be improved (this means: be reduced) by decreasing the extent of the deformation trough.

Sports Hall Surfaces

Let us now consider real sports surfaces. We will begin with surfaces for sports halls.

It had a positive effect in the practice of building new sports halls in Germany when in 1986 DIN 18032 introduced the distinction between various surface types according to their deformation characteristics. In the introductory part of the standard, the general performance effects are described as related to the use of the surface types:

DIN 18032 Part 2 Paragraph 3.1.2

The theoretical distinction and the information on the possible manifold of surface systems as resulting from theoretical considerations has encouraged the development of mixed-elastic and combined-elastic sports surfaces.

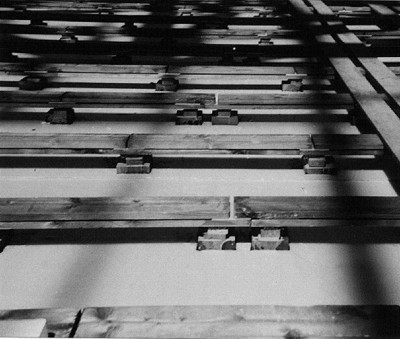

Area-elastic systems are typically produced as shown in fig. 5. They are called 'constructive swing floors' since their resilience is caused by the design of a sleeper system. It is inevitable that they are so-called 'average value' surfaces. This means that they meet the requirements of DIN 18032 by averaging the results of the different test locations. Since the resilience varies relative to the intersections of sleepers and the supporting pads, the uniformity of the mechanic properties across the surface is often insufficient. (From the table we can see the variances of the parameters = still to be drafted).

Figure 6 shows an extremely negative example of an aerea-elastic surface which is produced in Bavaria. This is to abuse of the gaps in the array of the DIN requirements. This example is worthy of mention since this surface is advertised with the slogan 'high tech' and is also accepted in the RAL quality monitoring program. The structure shows that the surface is simply misdesigned. Forces acting on this surface are diverted straight to the rigid pads and will not be cushioned by leading the load through sleepers to the underground as it should be with area-elastic surfaces. Consequently, it is typical for such surfaces that the resilience varies within the surface area between nearly nought and 3+ millimeters. Only by forming the average of all measuring locations/points will this type surface meet the DIN requirements.

This is a twofold violation of DIN 18032: according to the DIN, all points within the sports surface area shall meet the requirements and also the variation of the parameters within the surface area shall be small (this means: surface performance shall be as uniform as possible).

The misdesign is compounded by the sleeper alignment in continuous rows thereby butting the endings of the sleeper elements (about 4 m long) so that double stiff points are produced (see fig. 7).

Combined surface systems are created by installing a point-elastic surface over an area-elastic surface. By this, the advantages of both systems are combined and their disadvantages avoided. The advantages were recognized in Germany, and in Switzerland, these surface systems have been commercially successful.

A considerable improvement of the area-elastic surfaces is achieved through the development of the so-called Sandwich type surfaces. These consist, in principle, of a continuous elastic layer of synthetic foam and wooden or synthetic panels as load distribution slab. With this design, vibrations due to impacts of heavy balls or athletes are highly damped and compliance with DIN requirements is no problem. The effective mass is minimalized. This is achieved by reducing the extent of the deformation trough, the thickness of the load distribution slab and/or the use of light weight wooden panels. Furthermore, the elastic and damping properties of an elastic layer may be adjusted by combining appropriate materials. The uniformity and the damping characteristics can be observed in the recordings of the Artificial Athlete Stuttgart (see Fig. 8 - in prreparation).

The mixed-elastic type was developed in Germany. It is connected with the names of Mr. Höss and Mr. Wilms although others are challenging for patent rights. This surface type is available in different grades of area-elasticity. Depending on the type of use, one or the other variant is more suitable.

The key aspect in the design of mixed-elastic surfaces was: a small dynamically effective mass and a controlled size of the deformation trough. The difficulties to be mastered were mainly due to installation and material problems.

Thus, the development of sports hall surfaces has been so intensively influenced by the existence of DIN 18032 that it cannot be imagined without it. Now, it is necessary to improve the situation by effective application of the standard (i.e. no longer average surfaces). In this process, it should be noted that the existing requirement of the deformation trough size of combined-elastic surfaces of 5 % cannot with good reasons be justified. This was not discussed thoroughly enough when the DIN was prepared. There is no acceptable reason why the W500 value of such surfaces should follow a much tougher requirement than normal area-elastic surfaces (of course: no average compro-mise is applied).

That mixed-elastic surfaces systems function without problems is the result of systematic and uncompromised testing and quality monitoring (not necessarily based on the RAL program) which was carried out voluntarily by the appropriate companies.

At this point, let us refer to a common misunderstanding which has lead to unacceptable sports hall surfaces. In section 3.3.1, DIN 18032 specifies requirements on evenness. It defines tolerances depending on the distance of the 'measuring points'. The terms 'tolerances' and 'measuring points' are confusing and are interpreted arbitrarily in practice. As we understand it - and this was the intention when the standard was prepared -, the measuring point distance is the distance between adjacent peak and valley spots. The tolerance - although not absolutely correct - is the difference in height between adjacent peak and valley spots. When using a straight edge, the tolerance is equal to the gap underneath it. To define measuring point distance as the distance between two adjacent peaks of the surface profile would allow considerable unevenness which would be unacceptable according to the state of the art.

Let us now move to a special sector of sports surfaces: gym mats. Due to the large deformation of such surfaces, we recognize the dynamic behavior in usual video recordings. We clearly see how feet rebound upon landing. The often occurring uncertainties/instabili-ties of gymnasts are caused by too little damping (rebound of feet) and by the fact that the size of the deformation trough is too small in relationship to the magnitude of the deforma-tion. Change in this is unlikely since it is dependant upon the willingness of the manufacturers and representatives of gymnastic associations taking the driver's seat in the appropriate standardisation committee.

Synthetic Surfaces

Synthetic Surfaces are used for Light Athletic Areas as well as for Team Sports Areas. For the latter in principle, the same considerations apply as for sports hall surfaces. However, the practical realisation is much more difficult because of the fact that they are exposed to outdoor conditions.

The most acute issue are the light athletics surfaces.

Again and again, the question arises: how can we produce an ultra fast track and what should it look like. This is a one-sided question since it refers exclusively to short distance races of high performance athletes. However, there is evidence that light athletics areas are used by students and leisure athletes less frequently: in any case, the frequency and duration of exercise by these persons on synthetic surfaces is much less than those of high performance athletes. Furthermore, the protective function of a synthetic surface is less important since

- uncontrolled surface contacts are rare caused by the nature of the specific sport and

- long term deficiencies of leisure athletes are unlikely because of the relative low frequency of their light athletic activities.

In order to answer the question on the 'fast surface', very often the rule is cited that - by mechanical reasons - a surface must be faster the harder it is. This rule is not completely wrong. However, it is questioned by what amount the running speed will be changed if the hardness is increased by a certain amount: will the performance significantly or noticeably improved (problem of significant, quantitative effect; sensational threshold).

Fortunately, the apparent contradiction of the protective function and the sports function is eliminated by biomechanical studies of McMahon and Greene. The authors let model athletes run on specialized track surfaces which could be varied in their give. This work was performed in connection with the construction of a tuned track at Harvard University. They found that the performance was not noticeably affected when the surface is rather soft/flexible compared with the stiffness of the mechanical system of the runner. However, this proposition does not exist with the surfaces actually available and used in athletics facilities. But the small improvement of elasticity (in the sense of 'softer') causes a reasonable reduction of the peak forces on the foot when hitting the surface - an advantage towards protective function. This reveals that a reckless hardening of the surface will only harm, not help in any way.

A more detailed consideration of the question 'what an optimal light athletic surface looks like' should take into account two typical stress situations of an athlete running over a track:

case 1 = impact of the relatively unprotected foot

This situation is characterized by a large vertical impact component and a small horizontal component.

case 2 = Start and Sprint

The situation is characterized by a large horizontal force component which must be transmitted by the traction of the surface. Traction is based in short distance disciplines on the effect of spikes mostly (interlocking force transmission) and not on friction between shoes and surface.

For an engineer, the conclusion drawn from this is that a light athletic surface must be designed with at least two layers.:

- a soft base layer provides reduction of impact forces when the foot is placed on the surface

- a stiff upper layer provides good traction. Probably, it is necessary to add a fabric between the two layers in order to decrease the horizontal deformation which is caused by the fact that the upper layer is made of soft coating material for spikes use.

In any case, the surface must not be designed upside down: this means the upper layer must not be softer than the base layer.

Encapsulated Texture

In the USA, another proposal was made on how to improve the performance: forming the surface with an 'Encapsulated Texture" (Gormley Stadium in New Orleans). This is a surface texture similar to a sprayed plaster on walls. The texture is achieved by casting a PUR coating with an excess of EPDM granules. The surface is rough enough to hurt the athletes feet when only running. They will be seriously hurt when struggling and sliding over the surface with bare skin.

I have a sample of such an Encapsulated Texture here. The argument in favor of this texture is that - other than the granular textured surfaces - full performance will be available right after completion of the surface. With granular textured surface, you will have to wait for about a year until the loose surface granules causing the decrease in traction will have been removed. Regardless of this argument, granular textured surfaces can have their full performance after completion of the track if the surface is brushed with a cleaning machine removing all loosely bound granules.

The discussion with experts of the sports governing bodies revealed that such textures cannot be rejected according to the IAAF Performance Specifications. However, the implications should be noted in the assessment to indicate to the readers that liability problems will arise from this situation.

Test Methods

There are two methods available in sports surface technology which have been introduced internationally and shown to be reliable through experience: the Artificial Athlete Stuttgart and the Artificial Athlete Berlin. Both the devices are used from the USA to China. With them, we can test the suitability of athletic surfaces to a rather great extent (see presentation of Dr. Binder).

Beside these, other test methods are used operating with a rigid mass as a missile (Biomechanical Institut in Poitier and Biomechanical Laboratory of the Federal Technical University Zuerich). The performance of the surfaces is described by means of the characteristics Peak Force and Energy Return. Whereas the Peak Force is measured more or less directly by means of a force platform or acceleration pick-ups, the Energy Return must be calculated from the height of rebound after the impact.

Interpretation of these parameters is uncertain. Does an increase of Energy Return mean an advantage under all circumstances and at which quantitative amount does it affect the performance or sensations of the athletes. As far as I know, there is no persuasive answer to this question. Differences in certain characteristics which can be determined with test devices must not be presented as functionally effective without special evidence. An Energy Loss of 75 % (determined by means of a test device) must not be understood as the Energy Loss of an athlete.

Conclusion

There is no special need for the development of light athletic surfaces. The room for such development is limited by physical and functional reasons. It did not incidentally happen that the design or structure of light athletic surfaces has not greatly changed within the last 25 years. We have to acknowledge or admit that surface characeristics might be accessable to technical measuring and can be differentiated by that. However, this does not reflect the real effect on performance in any case. The decision between two very similar surfaces on superiority - in terms of performace/running speed - cannot be judged with any of the available test methods. The limits of technical testing must be recognized.

Thus, what are the factors influencing top athletic performance? Although I am not predestined to render a comment on this matter, I will formulate as follows:

Top athletic performance is achieved if

a) the surface and the rest of the sports facility is in good condition,

b) the athletes are well prepared for the event (timing of training preparation)

c) the psychological conditions are appropriate:

- enthusiastic spectators advertising and public response prior to the event money offered

- placing the event on the schedule of international sports events (a meeting just 1 or 2 weeks prior to the Olympic Games can rather be successfull)

Note

Precision of Test Methods

At this point, (although not actually belonging to the issue of my presentation) I would like to emphasize a very important proble

Lausanne: 28 & 29 November 2024

The ISSS has successfully concluded the AGM and the Technical Conference in Lausanne. Scientific and Individual Members present accepted financials, audit report and activity schedule as presented.

Details Here